Indium Alloys

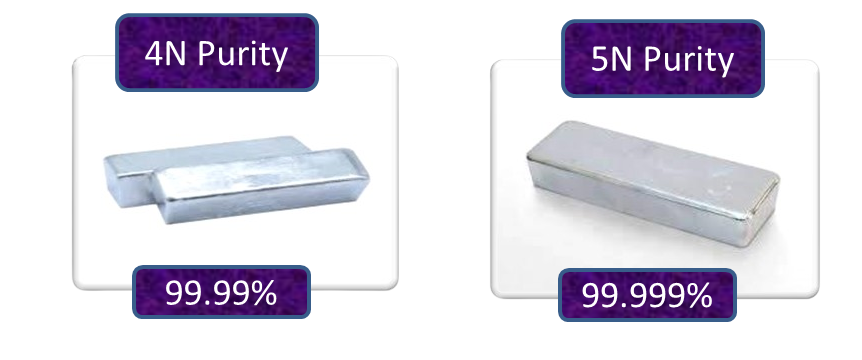

Indium metal is extracted primarily from indium-containing zinc or tin ores and is purified to various qualities using the latest refining technologies controlled by statistical processes.

JAYTEE produces and refines Indium in the United States, and Korea.Indium Alloys is also used in combination with various semiconductor oxides, where it plays its most valuable role as a transparent conductor. ITO (Indium Tin Oxide) is used in almost all flat and touch screens in use today. In fact, IGZO (the combination of indium, gallium and zinc oxides) is the material of choice in the future to form the pixel switching transistors in next-generation displays.

It expand slightly as they solidify and drive into the cracks in a mold to create detailed replicas. These alloys are useful for repairing dies, making fusible joints, and holding delicate parts for machining. Indium metal have a low melting temperature, so they can be poured into glass, quartz, mica and ceramic molds.

Applications For Low Melting Point Indium Alloys

Low-melting indium-based alloys can be found in a variety of applications, from castings to radiation therapy shielding. However, due to its soft nature, this alloy is often used in the manufacturing process itself to make and refine other products.

Due to their low melting and liquid state, indium-containing alloys are widely used for bending, anchoring, clamping or jigging. During the bending process, the low-melting alloy is placed in a pipe.

The melt solidifies and expands, filling the pipe and showing kinks or cracks. The tubing is then bent into the desired shape, as the indium-based alloy serves as the support. After the tube is bent, the alloy is heated in hot water, a hot oil bath, or an oven while the indium-based alloy is made liquid and completely removed.

In anchoring applications, the alloy wraps around the part as it expands and solidifies. The part can then be sanded and polished or held in place if used in sheet metal drilling applications. In the case of spectacle lenses, indium-based alloys are often applied during polishing. The alloy is then melted with warm water and used again.

For applications where extreme heating can occur, which can cause a dangerous situation, it can be used as a thermal fuse. When an application reaches a certain unsafe temperature, the alloy reacts and melts when the application enters safe mode to automatically unwind or shut down completely.

Additional applications for low indium include potting molds for electronic components, casting tools and electroforming mandrels. JAYTEE is the best indium alloys manufacturer, suppliers and distributors in India.